A lead-acid battery (VRLA) is a battery whose electrodes are mainly made of lead and its oxides and whose electrolyte is a sulfuric acid solution. Lead-acid batteries have a high current capacity, low cost and are easy to abuse. In the discharged state of the lead-acid battery, the main component of the positive electrode is lead dioxide, and the main component of the negative electrode is lead; in the charged state, the main components of the positive and negative electrodes are lead sulfate.

The lead-acid battery does not need to be added with acid and water for maintenance. The battery is a sealed structure that will not leak acid or discharge acid mist. The battery cover is provided with a one-way exhaust valve (also called a safety valve). The function of this valve is When the amount of gas inside the battery exceeds a certain value (usually expressed as a pressure value), that is, when the pressure inside the battery rises to a certain value, the exhaust valve automatically opens to exhaust the gas, and then automatically closes the valve to prevent air from entering the battery.

For a lead-acid battery to generate a voltage, it must first receive a (shaped) charging voltage of at least 2.1 volts/battery from the charger. Lead-acid batteries do not generate their voltage; they only store charges from other sources. This is why lead-acid batteries are called accumulators because they only store charge. The size of the battery plate and the amount of electrolyte determine the amount of charge that the lead-acid battery can store. The size of this storage capacity is described as the ampere-hour (Ah) rating of the battery.

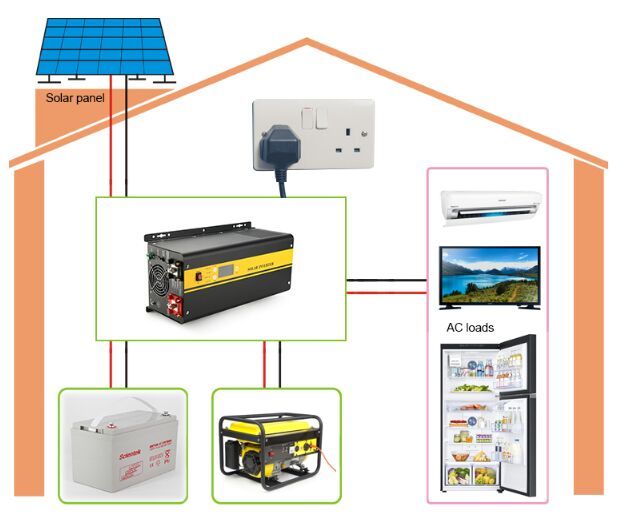

The lead-acid battery is connected to the UPS host. When the mains power is normal, the UPS host charges the battery, converts the electrical energy into chemical energy, and stores the energy. The battery is the core part of the UPS power system, so its performance is good or bad. It is also directly related to whether the UPS power supply can provide effective power failure protection for the equipment.

The grid structure of the lead-acid battery is made of lead alloy. Pure lead is too soft to support itself, so a small number of other metals are added to obtain mechanical strength and improve electrical performance. The most common additives are antimony, calcium, tin, and selenium. These batteries are commonly referred to as "lead-antimony" and "lead-calcium". Lead-acid maintains a strong lead content in the starter battery. Good low-temperature performance, low cost, good safety record, and easy recycling are reliable.

Lead-acid batteries have better self-discharge characteristics. At room temperature of 20°C, the monthly self-discharge rate is about 3%. >In theory, lead-acid batteries can be stored for up to 12 months without recharging. However, at higher temperatures, self-discharge is higher. At 30°C, the self-discharge will increase and it will need to be recharged after six months. Letting the battery fall below 60% will cause sulfation.

Commonly used lead-acid batteries are mainly three types: ordinary batteries, dry-charged batteries, and maintenance-free batteries:

1) Ordinary battery; the polar plate of ordinary battery is composed of lead and lead oxide, and the electrolyte is an aqueous solution of sulfuric acid. The main advantages are stable voltage and low price, but the specific energy is low (that is, the electric energy stored per kilogram of storage battery), the service life is short and the daily maintenance is frequent.

2) Dry-charged battery: its full name is the dry-charged lead-acid battery, the main feature is that the negative electrode plate has a higher power storage capacity, and in a completely dry state, it can save the obtained power within two years. When used, Just add electrolyte and wait for 20-30 minutes before using it. The structure of the dry-charged battery is the same as that of the general lead-acid battery, except that its polar plate adopts a special process.

For example, rosin, oleic acid, stearic acid, and other antioxidants are added to the lead paste of the negative plate. When the polar plate is formed, the formation time is appropriately extended, or a deepening method of charging-discharging-recharging is adopted to maximize the conversion of the active material. After the formation of the negative electrode plate, it should be put into an antioxidant solution [boric acid, salicylic acid mixed solution] for immersion treatment to form a protective film on the surface of the negative electrode plate. Finally, the electrode plate is dried in inert gas. The electrode plate produced in this way can store the electric charge obtained in the manufacturing process for a longer period of time under the condition of a dry state.

3) Maintenance-free battery: The maintenance-free battery is made of lead-calcium alloy. Because the battery uses lead-calcium alloy as the grid, the amount of water decomposition during charging is low, and the amount of water evaporation is also low. The sulfuric acid gas released is also very small, so it has no need to add any liquid compared with the traditional battery, less corrosion of the wiring pile head, wire and car body, strong resistance to overcharge, large starting current, long storage time of electricity, etc. advantage.

Due to its structural advantages, the maintenance-free battery consumes very little electrolyte and basically does not need to add distilled water during its service life. It also has the characteristics of shock resistance, high-temperature resistance, small size, and small self-discharge. The service life is generally twice that of ordinary batteries. There are also two types of maintenance-free batteries on the market: the first one is to add electrolyte at the time of purchase and it does not require maintenance after use (adding supplementary liquid); the other is that the battery itself has been filled with electrolyte and sealed off when it leaves the factory. , The user can't add supplemental liquid at all.

According to dry and wet conditions, it can also be subdivided into dry batteries and wet batteries:

The dry battery belongs to the primary battery in the chemical power supply and is a disposable battery. Because the electrolyte of this chemical power supply device is a non-flowable paste, it is called a dry battery, which is relative to a battery with a flowable electrolyte. You can add battery water, but do not exceed the maximum water level, generally marked with MAX line.

Dry-charged lead-acid batteries (such as automobile dry-charged batteries, motorcycle dry-charged batteries, etc.) should be supplemented with distilled water after a period of use so that the density of dilute sulfuric acid electrolyte is maintained at about 1.28g/ml; for maintenance-free batteries, they are used until their lives No more distilled water is required for termination.

2) The wet battery is a lead-acid battery, which is formed by a solution of flowing acidic water.

Generally speaking, 80% of batteries are distinguished by color: white is a water battery, black is a dry battery; lightweight is a water battery, and heavy is a dry battery; from the appearance accessories: the water screw on the battery is Water, flat head is dry.

The main characteristics of the battery:

Safety seal

During normal operation, the electrolyte will not leak out of the battery terminals or casing. No free acid

The special liquid-absorbing separator keeps the acid inside. There is no free acid inside the battery, so the battery can be placed in any position.

Vent system

After the internal pressure of the battery exceeds the normal level, the VRLA battery will release excess gas and automatically reseal it to ensure that there is no excess gas in the battery.

Simple maintenance

Since the gas recombination system converts the generated gas into water, no water needs to be added during the use of VRLA batteries.

Long-lasting

The VRLA battery with lead-calcium alloy railing with anti-corrosion structure can be float-charged for 10-15 years.

Stable quality and high reliability

Using advanced production technology and strict quality control system, VRLA battery has stable quality and reliable performance. 100% inspection of voltage, capacity, and sealing on the line.

safety certificate

All VRLA batteries have passed UL safety certification.

(1) To avoid direct contact between the battery and the metal container to prevent short circuits, acid-proof and heat-resistant materials should be used, otherwise, it will cause smoke or fire.

(2) Use the specified charger to charge under the specified conditions, otherwise, it may cause the battery to overheat, deflate, leak, burn, or rupture. Ordinary lead-acid batteries should pay attention to regularly add distilled water. It is best to charge the dry-charged battery properly before use. As for the maintenance-free battery that can be added with water, it is not impossible to maintain it properly. Checking if necessary, supplementing distilled water helps extend the service life.

(3) Do not install the battery in a sealed device, otherwise, the device may be broken. There is often a yellow-white paste around the battery pole and cover, which is caused by sulfuric acid corroding the root post, line card, fixing frame, etc. The resistance of these substances is great and must be removed in time.

(4) When using the battery in medical equipment, please install a backup power supply other than the main power supply, otherwise, the failure of the main power supply may cause injury.

(5) Keep the battery away from equipment that can generate sparks, otherwise, sparks may cause the battery to smoke or rupture. The direct ignition (short circuit test) method cannot be used to check the battery power, which will cause damage to the battery.

(6) Do not place the battery near a heat source (such as a transformer), otherwise, it will cause the battery to overheat, leak, burn or rupture.

(7) When there is more than one battery in the application, please make sure that the connections between the batteries are correct and that they are connected to the charger or the load, otherwise it will cause the battery to rupture, burn or damage the battery, and in some cases will hurt people. Always check whether the pole and terminal are connected reliably. In order to prevent terminal oxidation, you can apply protective agents such as petroleum jelly.

(8) Check whether the fixing bolts of the battery on the bracket are tightened. If the installation is not reliable, the casing will be damaged due to vibration.

(9) Do not use the battery in a place full of dust, it may cause a short circuit of the battery. When using the battery in a dusty environment, check the battery regularly. The air holes on the battery cover should be unobstructed. A large number of bubbles will be generated when the battery is charged. If the vent hole is blocked so that the gas cannot escape. When the pressure increases to a certain level, the battery case will burst.

(10) Do not put the battery mounted on the locomotive under high temperature, direct sunlight, stove, or fire, otherwise, it may cause the battery to leak, catch fire, or rupture. When it is necessary to use two batteries in series, the capacity of the batteries is preferably equal. Otherwise, it will affect the service life of the battery.

UPS lead-acid batteries, charging and discharging, is called a cycle (one cycle). Under certain discharge conditions, the number of cycles the battery can withstand before the battery reaches a certain capacity is called the cycle life. The cycle times of various storage batteries are different. The traditional fixed lead-acid battery is about 500 to 600 times; the start-up lead-acid battery is about 300 to 500 times; the valve-regulated sealed lead-acid battery cycle life is 1000 to 1200 times.

To charge lead-acid batteries, the most important thing to understand is that a converter/charger with a single fixed output voltage will not be able to properly charge or maintain the battery. Correct charging and maintenance require an intelligent charging system, which can change the charging voltage according to the state of charge and the use of RV or marine batteries. During the charging process, when current flows through the water portion of the electrolyte and water, (H2O) is converted to the original elements of hydrogen and oxygen.

All batteries, regardless of their chemical nature, will self-discharge. The self-discharge rate of lead-acid batteries depends on the storage or operating temperature. At a temperature of 80 degrees Fahrenheit, lead-acid batteries will self-discharge at a rate of about 4% per week. A battery rated at 125 amps will self-discharge at a rate of about 5 amps per week. Keep in mind that if a 125 AH battery is not charged for four months (16 weeks) in winter, it will lose 80 amps of its 125 amp capacity. It will also undergo severe sulfation reactions, leading to further loss of capacity. Charge the battery when not in use!